From Spreadsheets to Smart Roasting: How We Built Our Own Roasting Companion App

Intro

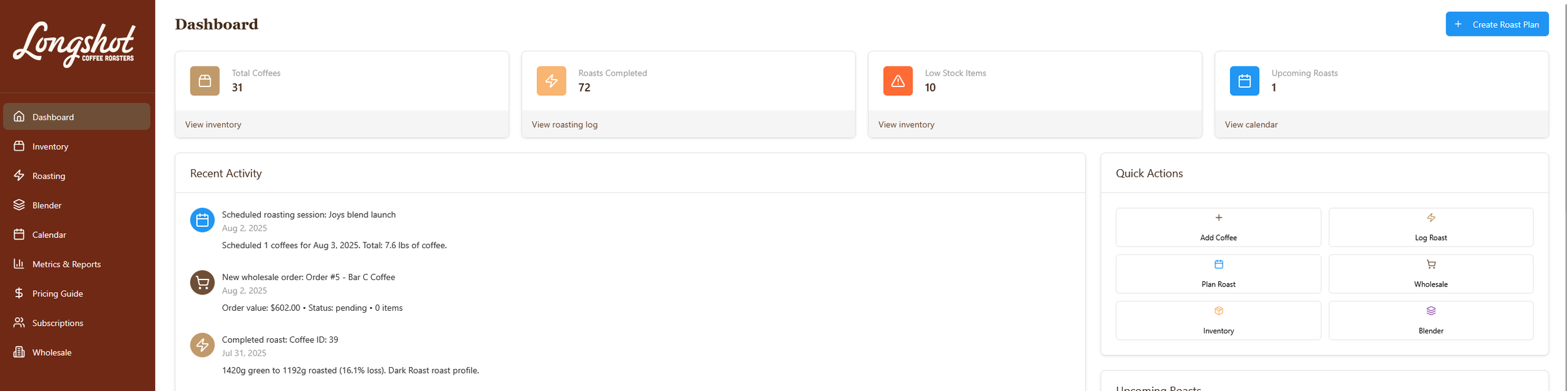

At Longshot Coffee Roasters, every batch starts with intention, not just in the beans we source or how we roast, but in how we plan and track every step. We needed a better system. So we built one. No engineering degree. No fancy dev team. Just a practical need, a lot of time in spreadsheets, and a lot of help from AI coding tools.

(2025) Live Dashboard View

Section: Where It Started

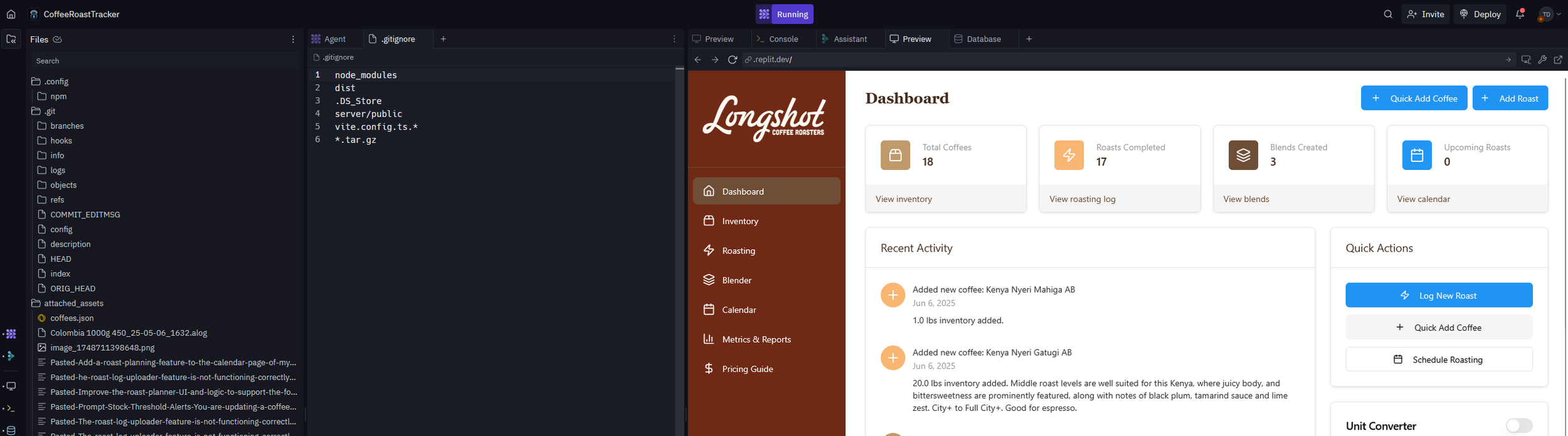

It all started after listening to a podcast with the CEO of Replit. He made the case that coding is no longer just for engineers, that anyone with a clear goal (and a little help from AI) can build what they need. That stuck with us. At the time, we were using spreadsheets to log our roasts, track green inventory, and estimate losses. It worked, but it wasn’t scalable.

So we prototyped our first tool; right inside a browser.

(2024) This is where we started.

I wish that I had a picture of the first iteration that replit help me design, but I do not :/

Section: The First Version

We called it the Coffee Roast Tracker.

This first version lived in Replit. It let us:

Manually log roast data

Track how much green coffee we had left

See simple summaries of usage

That was enough for a while. But as we grew, we needed more control and better integration. So we moved the project to GitHub Copilot and started coding it locally in VS Code.

Currently the program is hosted on our server computer in our home streaming out through tailscale connected devices. This allows us to plug in at our roastery, or from wherever we are since there is mobile functionality as well.

Section: Features That Changed Everything:

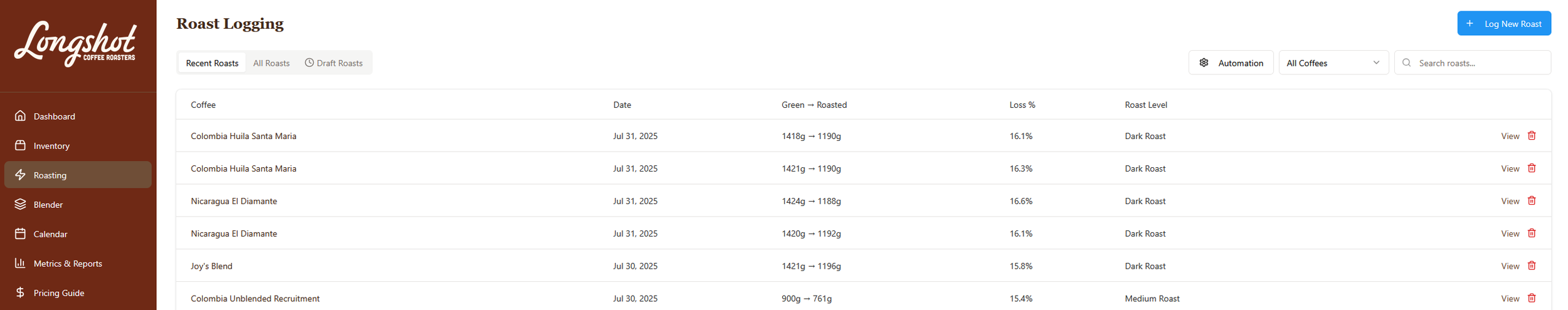

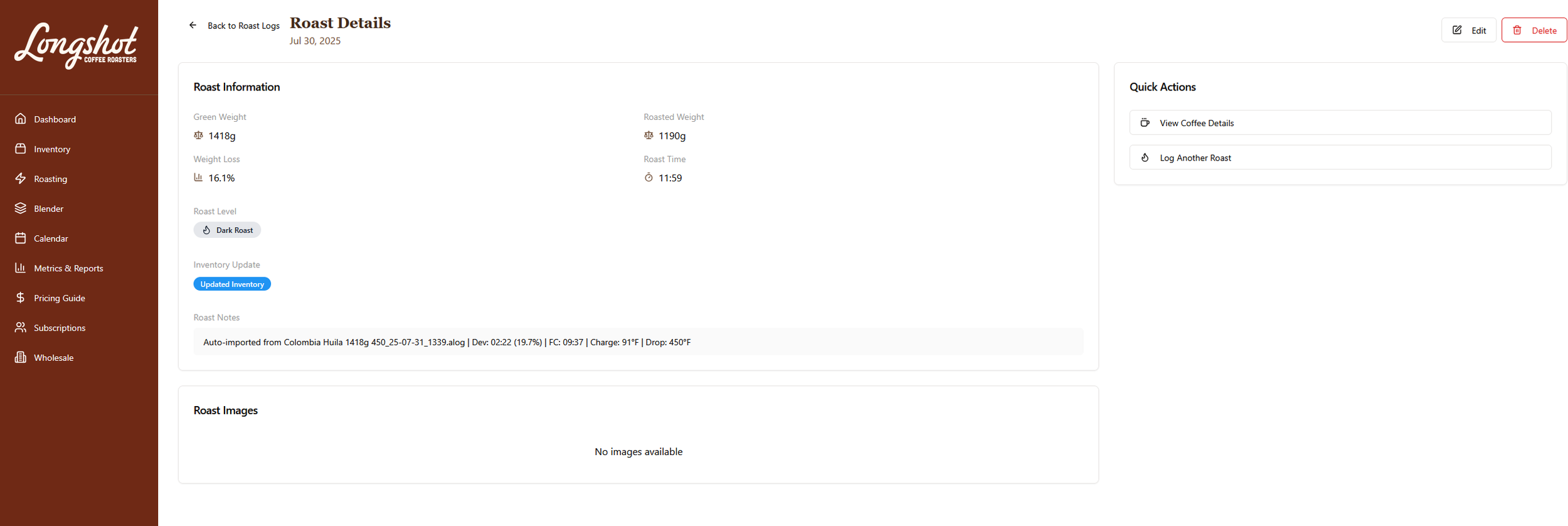

1. Automatic Tracking with Artisan

We connected the app to our roasting computer. Now, every time we finish a roast and save the .alog file, the app:

Reads the file

Tracks the initial green weight

Parses the coffee’s name

Estimates weight loss based on drop temp

Saves as a draft

Updates inventory in real time

No more manual inputs. No more guesswork.

(2025) Live View of Roasting Page

(2025) Live View of the Roast Details Page (Side note I want to incorporate roasting graphs to parse here as well.)

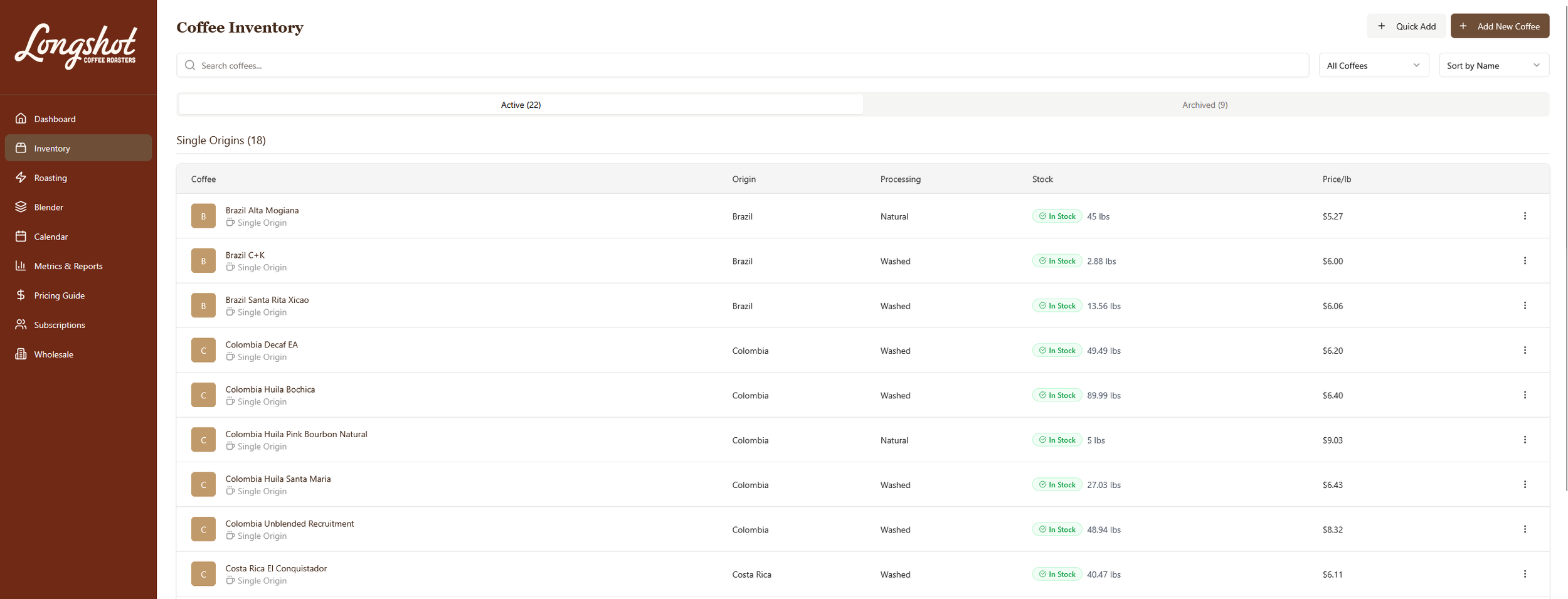

2. Real Inventory + Blend Planning

We started with inventory tracking. Inputting total weight, price per pound, price for shipping. Then we connected our roasting data to automatically subtract initial green coffee weight from the inventory in order to have accurate counts on hand.

Blender was next. A seemingly simple, yet frustrating for me job was calculating blend costs by hand or spreadsheet. So I knew that I wanted to make it easy to track and manage blends with our app. The first thing that we did was link the inventory to the blender page. Now the functionality works by creating a blend you can add as many coffees from the inventory to the blend and the percent for each coffee. The app will calculate the percentages, and give you a price per pound for the total blend since each single origin coffee has a different cost.

(2025) Live View of the Inventory Page

3. Roasting Calendar

Here is an interesting problem with coffee roasting and tracking. Coffee loses weight when its being roasted. The water in the green beans evaporates and then eventually the energy of the water explodes (first crack). Depending on the roast level and green coffee the weight loss will be different. This matters for us because if we are roasting for 1-2 customer only a couple of bags we do not want to roast too much or too little (time is money, and coffee beans are money, precision is key). Plus we are already tracking how much coffee we are roasting every batch for precision and for inventory tracking.

This led us to one of our most proud features that we implemented: the roasting calendar. Here we are able to create order tickets that allow us to input exactly what a customer ordered. Single origin or blends and then based on the roast level that they ordered it will give me the exact amount of green coffee needed to fulfill that order. We still need to rub our eyes and pinch ourselves every time, but by golly math works, every time. We programmed it to over shoot the roast loss percent by 1-2% to have a little more than we need for the order (just in case)

(2025) Live View of the Customer Roast Plan

(2025) Here is what that printable ticket looks like.

4. Metrics & Reporting

This one is pretty boring at the moment. It is a reporting page that gives us overarching numbers.

5. Price Guide

We built a tool that lets us break down cost by:

Coffee per pound

Packaging

Electricity

(Optional) Labor/time

We are a small business working with small margins! So creating this tool has been paramount mostly for ensuring that we aren’t losing money anywhere. Its gotten close a few times.

(2025) Yeah, this pricing guide is really just cost of goods, not including rent, insurance, payroll, utilities. So when you see 100% profit margins do not get too excited.

What’s Next

Here’s what we’re currently working on:

Streamlining + Bug Fixes

Optional web integration (for syncing with our site)

Subscriptions

Wholesale partners

Conclusion

We didn’t set out to become developers. We just needed a better way to run our coffee business.

Now we have a system built for the way we roast. And it’s growing with us; one feature at a time.